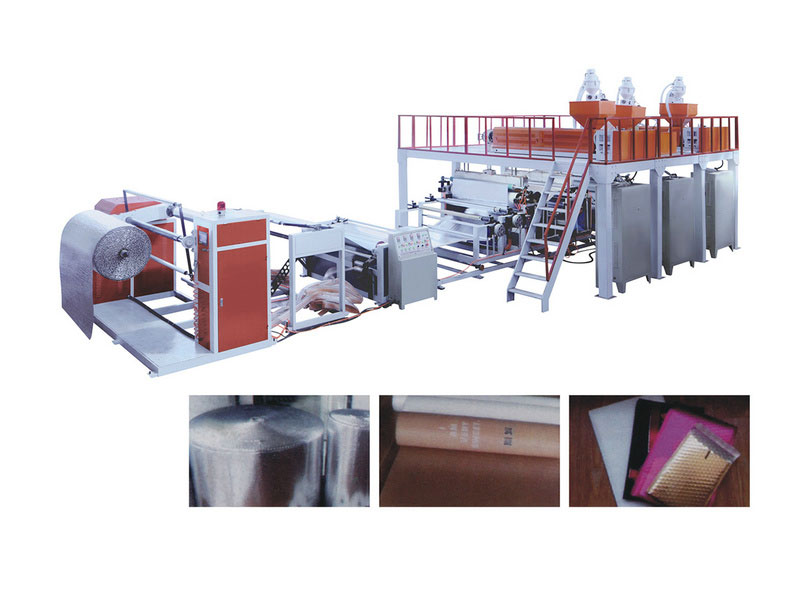

1000mm / 4 Layers / 2 Screw / 2 Die Head / 1 Un-winder

1.Extruder Unit: Gearbox; Screw; Motor; Die Head

1.Automatic Cutter and Re-winder

|

Bubble film width (mm) |

1250 |

1500 |

2000 |

2500 |

3000 |

|

Model number |

UTOPE-4L2S-1250 |

UTOPE-4L2S-1500 |

UTOPE-4L2S-2000 |

UTOPE-4L2S-2500 |

UTOPE-4L2S-3000 |

|

Raw material |

LDPE/LLDPE |

||||

|

Line speed (m/hr) |

800 - 2100 |

800 - 2100 |

800 - 2100 |

800 - 2100 |

800 - 2100 |

|

Capacity (kg/hr) |

80 - 100 |

100 - 140 |

110 - 158 |

120 - 180 |

160 - 220 |

|

Thickness (g/m2) |

38 - 300 |

38 - 300 |

40 - 300 |

45 - 300 |

45 - 300 |

|

Main screw diameter (mm) |

Φ75 |

Φ75 |

Φ80 |

Φ90 |

Φ130 |

|

Sub screw diameter (mm) |

Φ50 |

Φ50 |

Φ65 |

Φ75 |

Φ80 |

|

Heating power (kw) |

72 |

88 |

110 |

130 |

168 |

|

Operation power (kw) |

36 |

44 |

55 |

69 |

79 |

|

Installation power (kw) |

100 |

136 |

159 |

202 |

254 |

|

Dimension L*W*H (m) |

12* 4.5 * 2.8 |

12 * 5 * 2.8 |

13 * 5.2 * 2.8 |

14 *5.5 * 3.5 |

15*6*3.6 |

|

Weight (kg) |

6500 |

7000 |

8000 |

9000 |

11800 |

Three screws design machine parameter

|

Bubble film width (mm) |

1250 |

1500 |

2000 |

2500 |

3000 |

|

Model number |

UTOPE-4L3S-1250 |

UTOPE-4L3S-1500 |

UTOPE-4L3S-2000 |

UTOPE-4L3S-2500 |

UTOPE-4L3S-3000 |